135-6822-2642

135-6822-2642

135-6822-2642

135-6822-2642

Date of establishment

Honorary Certificates

(㎡)Corporate Headquarters

(ten thousand)Registered capital

(Billion)Total investment in the factory

Fiberglass composites are widely used in the manufacture of yacht hulls and decks due to their corrosion resistance, light weight and good increase effect.

Service hotline:159-2855-2321

Service hotline:159-2855-2321

The application of glass fiber reinforced composites in electronic and electrical fields mainly makes use of its electrical insulation, corrosion resistance and other characteristics.

Service hotline:159-2855-2321

Service hotline:159-2855-2321

Glass fiber composite materials have good corrosion resistance, good increase effect and other characteristics, and are widely used in the chemical industry, manufacturing chemical containers (such as tanks), anti-corrosion gratings and so on.

Service hotline:159-2855-2321

Service hotline:159-2855-2321

Composite materials have obvious advantages over traditional materials in toughness, corrosion resistance, wear resistance and temperature resistance, and meet the requirements of transportation tools for light weight and high strength, so they are more and more widely used in the automotive field. Typical applications are

Service hotline:159-2855-2321

Service hotline:159-2855-2321

Wind energy and photovoltaic are both low pollution and sustainable energy sources. Glass fiber is a good material for making glass fiber reinforced plastic blades and machine covers because of its advantages of increasing effect and light weight.

Service hotline:159-2855-2321

Service hotline:159-2855-2321

Glass fiber has the characteristics of good size, good reinforcement performance, light weight and corrosion resistance compared with steel, concrete and other materials, making it an ideal material for manufacturing bridges, wharfs, expressway pavement, trestles, waterfront buildings, pipelines and other infrastructure.

Service hotline:159-2855-2321

Service hotline:159-2855-2321

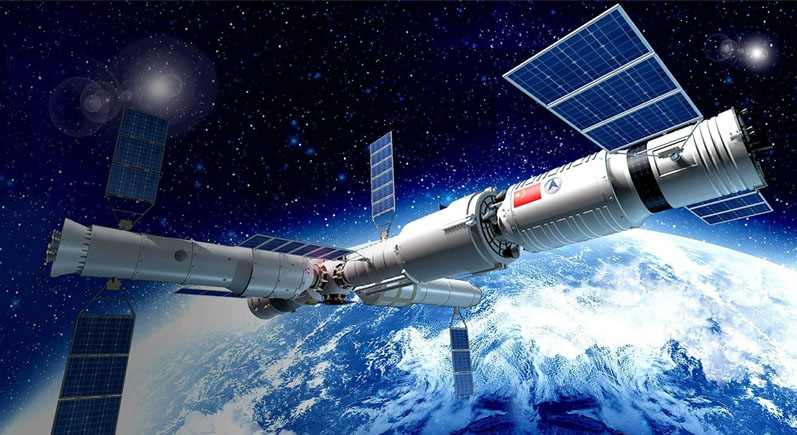

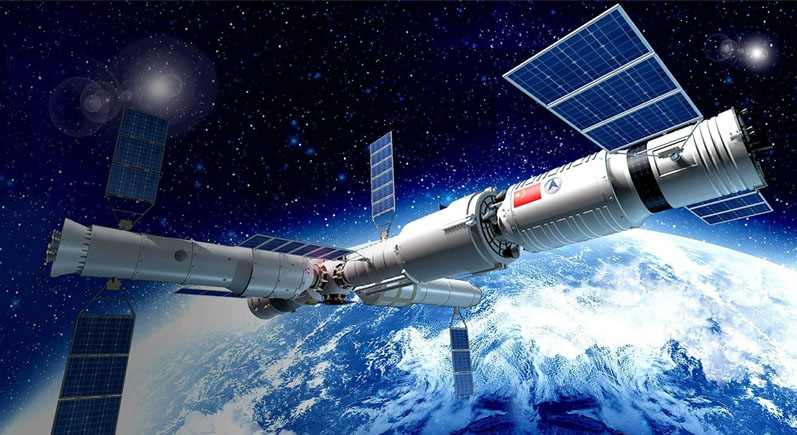

Due to the special requirements for materials in aerospace, military and other fields, glass fiber composites have the characteristics of light weight, high strength, good impact resistance and flame retardancy, which can provide a wide range of solutions for these fields.

Service hotline:159-2855-2321

Service hotline:159-2855-2321

Focus on the production and operation of high-performance glass fiber yarn, cloth and glass fiber deep processed products

With ingenuity, we only bring you high-quality products

Focus on glass fiber processing

Roving Fine Making

quality testing

After sales guarantee

We are specialized in glass fiber yarn, cloth and glass fiber deep processing products

The product specifications are complete, mainly including glass fiber twisted roving, direct twistless roving, twisted yarn, mesh cloth, etc

The product has good performance index and stable and reliable quality.

The design and construction technology of large-scale alkali free tank kilns and environment-friendly tank kilns with completely independent intellectual property rights;

Pure oxygen combustion technology is adopted and industrialized application is carried out

The glass formula design with environmental protection and high performance greatly reduces the energy consumption per unit capacity.

Quality inspection of products at all levels and spot check in batches to ensure high standards and quality of products

The products delivered meet the standard requirements or contract standards

With 20+patents and software copyrights, and the quality of ingenuity, we will serve you wholeheartedly!

Create excellent and reassuring products for users, provide 7 * 24h butler type after-sales service, and provide efficient offline and online solutions

360 degree service system, so that you have no worries;

Perfect logistics distribution center, products are sold everywhere

We serve every customer with our heart

Demand survey

field survey

conceptual design

Sign the contract

Field installation

delivery

after-sale service

Passed national certification, testing and reporting

Acoustic performance and application of glass fiber cloth ZL rubber powder polyphenyl particle thermal insulation material:

The system itself has an air layer that is connected as a whole. In case of fire, a pilot air duct will be formed quickly to spread the fire rapidly. The external thermal insulation system of polystyrene board exterior wall will shrink and melt quickly under high temperature radiation

Requirements for glass fiber cloth wall insulation and facing brick: When the anti-crack mortar reaches the initial setting strength, it should be properly sprayed for curing. After about 7 days, it can be divided and snapped according to the requirements of the drawing.

1. The flatness of the base wall cannot meet the requirements.

Generally speaking, after the construction of cement-based materials, certain measures shall be taken for curing.

1、 Glass fiber is the mainstream reinforcing material, and technology drives the upgrading of product structure

Human body temperature is basically stable, with a small range of change, and does not change with the rise and fall of the external temperature.

When lapping the grid cloth, the general requirement is not less than 50mm. In the thermal insulation construction, the special parts prone to cracks are also strengthened.

Founded in 2018, the company is a production enterprise mainly engaged in the production and operation of high-performance glass fiber yarn, cloth and glass fiber deep processed products. The company is located in Luojiang District, Deyang City, Sichuan Province, with a registered capital of 43.33 million yuan. The product specifications are complete, mainly including glass fiber twisted roving, direct twistless roving, twisted yarn, checkered cloth, gridding cloth and other products, with excellent performance indicators and stable and reliable quality. The total investment of the factory is 238 million yuan, and the design and construction technology of large-scale alkali free tank kilns and environment-friendly tank kilns with completely independent intellectual property rights are available; The electric furnace aid and pure oxygen combustion technology are adopted and industrialized. The glass formula design with environmental protection and high performance greatly reduces the energy consumption per unit capacity. The company was officially put into production in June 2022. At present, the company has a wide range of products. It has adopted a completely independent sizing agent formula design, adhering to the differentiation strategy of "roving fine making". The products have been introduced to the market, unanimously recognized by customers, and the industry position has gradually improved.