135-6822-2642

135-6822-2642

135-6822-2642

135-6822-2642

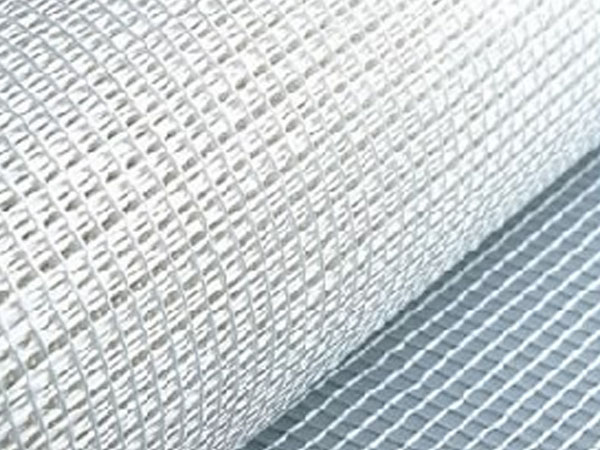

Glass fiber checkerboard is a kind of roving plain fabric without twist, which is an important base material for hand laid FRP. The strength of checkered cloth is mainly in the warp and weft direction of the fabric. For the occasion requiring high warp or weft strength, it can also be woven into one-way cloth. It can arrange more rovings, single warp cloth and single weft cloth in the warp or weft direction.

The glass fiber cloth is used to draw the glass into very fine glass fiber, which has good flexibility. The glass fiber can be spun into yarn and then woven into glass fiber cloth through a loom. As the glass fiber is very thin and the surface area per unit mass is large, the temperature resistance is reduced. Just like a candle can melt a thin copper wire. But glass does not burn. The combustion we can see is actually the resin material coated on the surface of the glass fiber cloth, or the impurities attached, to improve the performance of the glass fiber cloth. After the pure glass fiber cloth or some high temperature resistant coatings are coated, it can be used to make fire-resistant clothing, fire-resistant gloves, fire-resistant blankets and other products. However, if it directly contacts the skin, the broken fiber will stimulate the skin greatly and will itch.

Glass fiber cloth is mostly used for hand pasting process. Glass fiber reinforced square cloth is mainly used for hull, storage tank, cooling tower, ship, vehicle, tank and building structural materials. Glass fiber cloth is mainly used in industry for heat insulation, fire protection and flame retardancy. The material absorbs a large amount of heat when it is burned by the flame and can prevent the flame from passing through and isolate the air.

1. According to composition: mainly including medium alkali, non alkali, high alkali (it is used to classify the alkali metal oxide components in glass fiber), and of course, there are also other components, but there are too many varieties to list one by one.